position: HOME > PRODUCTS > Longitudinal Seam Welding Machine

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

Product introduction:

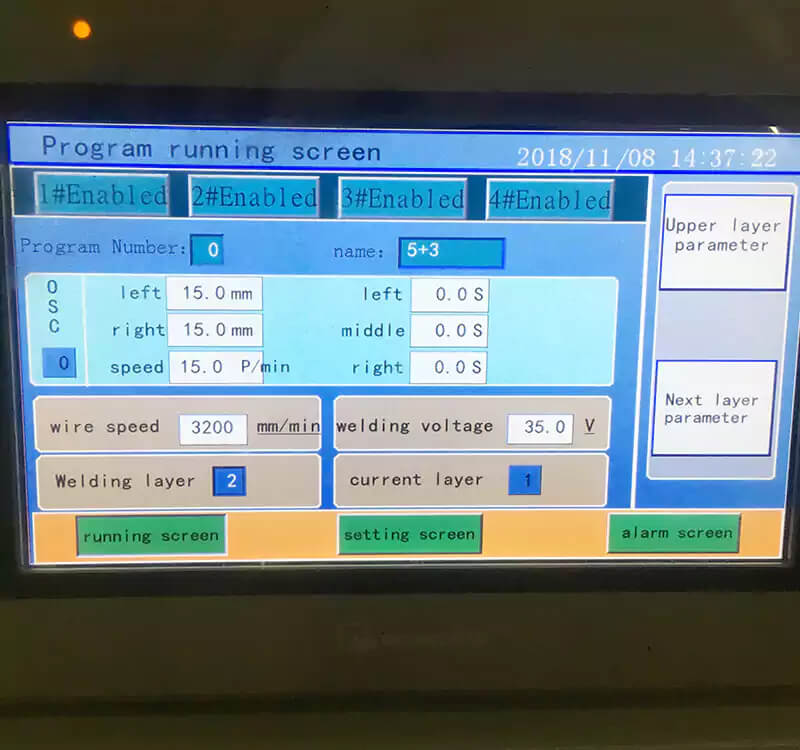

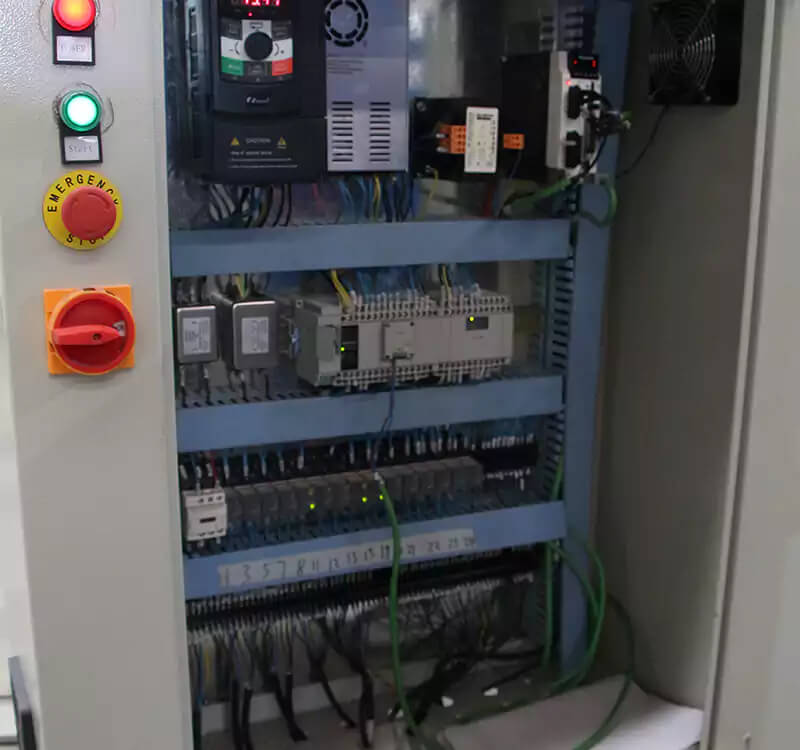

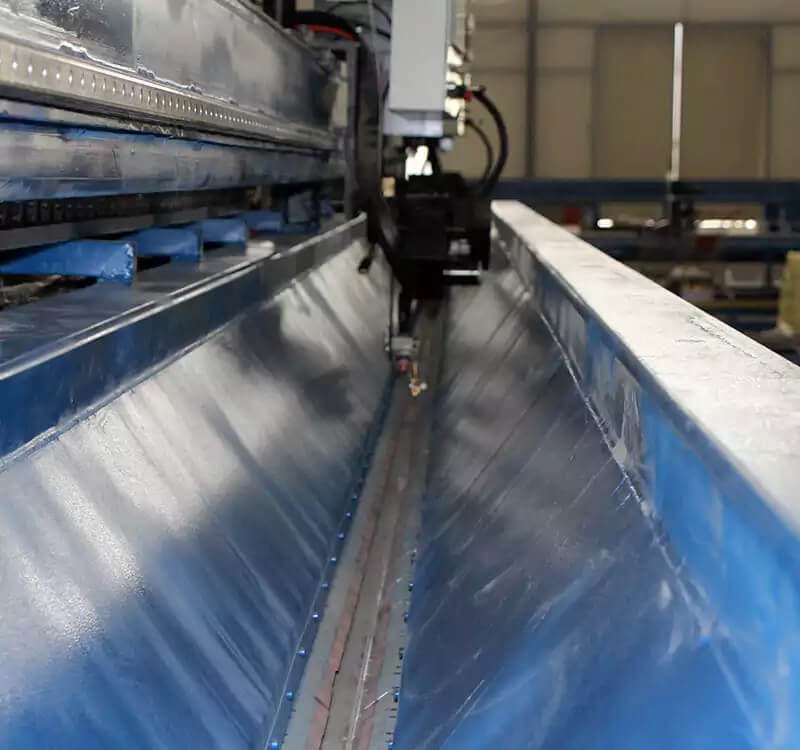

The automatic long longitudinal seam welding machine is mainly used for automatic welding of the longitudinal seam in plate splicing. The welding technology can be used in TIG/MIG/MAG/PWA/SAW and other ways. It is suitable for welding of carbon steel, stainless steel, aluminum and aluminum alloy, titanium alloy, and other materials. It is widely used in aerospace, automobile parts, motorcycles, household appliances, pressure vessels, and food. Products machinery and other industries. The equipment adopts pneumatic keyboard pressing structure to ensure uniform pressing of the workpiece, water cooling of mandrel and back gas protection of welding seam can be selected to reduce welding deformation, and PLC + human touch operation interface is adopted in the control system to effectively ensure welding quality and simple and reliable operation.

Standard configuration:

Support mandrel (without water cooling), copper welding pad (the size of the groove formed by the pad is determined by the thickness of the workpiece, material, and welding process), copper keypress fingers, 100mm welding gun pneumatic lifting mechanism (bearing 20kg), 60mm Stroke two-dimensional manual adjustment mechanism, universal arc welding controller (suitable for TIG / MAG / PAW).

Optional functions:

Water-cooled support mandrel, back gas protection pad, stainless steel pad, pneumatic/manual centering device, TIG wire feeding device, ALC arc length tracker, pneumatic hook, electric cross slide, welding seam tracking device, Auxiliary loading and unloading trolley, submerged arc welding head and controller.

Features:

1. The mainframe uses high-quality raw materials and adopts a frame-type welding structure to meet the stability of the equipment during long-term use. The base can be fixed with an anchor screw. The equipment has a compact structure, a small footprint, and convenient workpiece lifting.

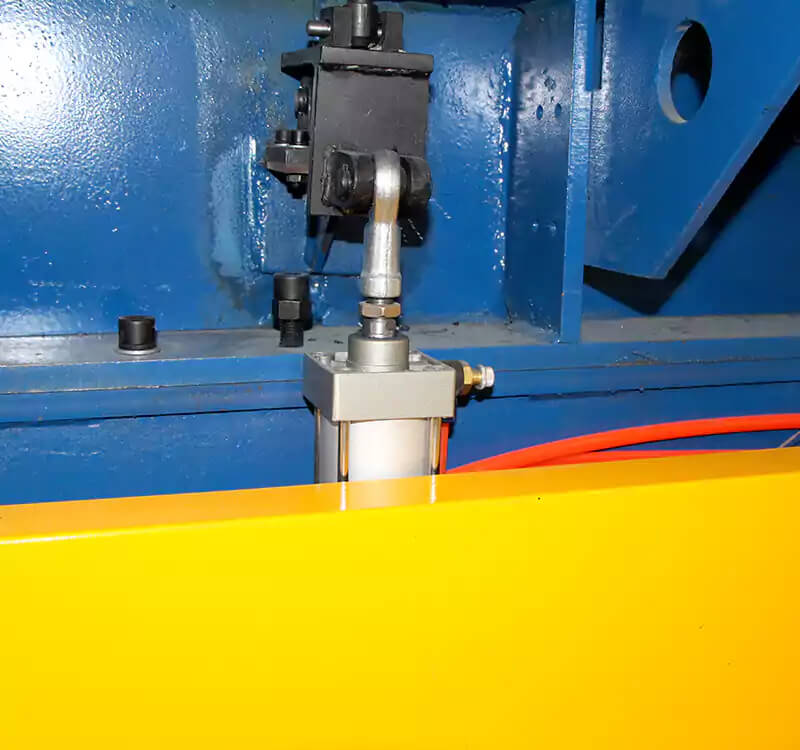

2. It adopts a key pressing mechanism to provide a uniform and stable working clamping and cooling effect. The workpiece is uniformly stressed and has small deformation. It is a reliable guarantee for the high-quality, efficient, and deformation-free welding of thin-walled workpieces.

3. The welding process has a back-gas protection function, which blocks the reaction with the air to ensure the beautiful appearance of the weld.

4. According to the product structure characteristics, standard series can be selected, and special customized equipment can be provided according to requirements.

Product parameters:

Product Model | PB-3000 | PB-4500 | PB-6000 | PB-9000 |

| Weldable Workpiece Length | ≤3900mm | ≤4500mm | ≤6000mm | ≤9000mm |

| Weldable Workpiece Sheet Thickness | 3.0-8.0mm | |||

| Head speed | 0-4000mm/min | |||

| Welding torch lifting stroke | 100mm | 200mm | ||

| Welding torch fine-tuning stroke | Y=100mm,Z=100mm | |||

| Specification of Controller Power Supply | Single-phase AC220v 50Hz | |||