position: HOME > PRODUCTS > Welding Positioner

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

The price of the machine will be different due to factors such as parameters and configuration. For specific prices, please contact our sales staff. He will help you choose the appropriate parameters and configurations and will give you a quotation.

Product introduction:

The welding turntable is a welding displacement machinery that rotates the welding piece around a vertical axis or an inclined axis. Mainly used for welding, surfacing, and cutting of weldments. The welding rotary table is mostly driven by a DC motor, and the table is adjustable at a uniform speed. For large welding turntables that rotate around a vertical axis, to support rollers are provided for the worktable surface, and assembly work can also be performed on the worktable surface.

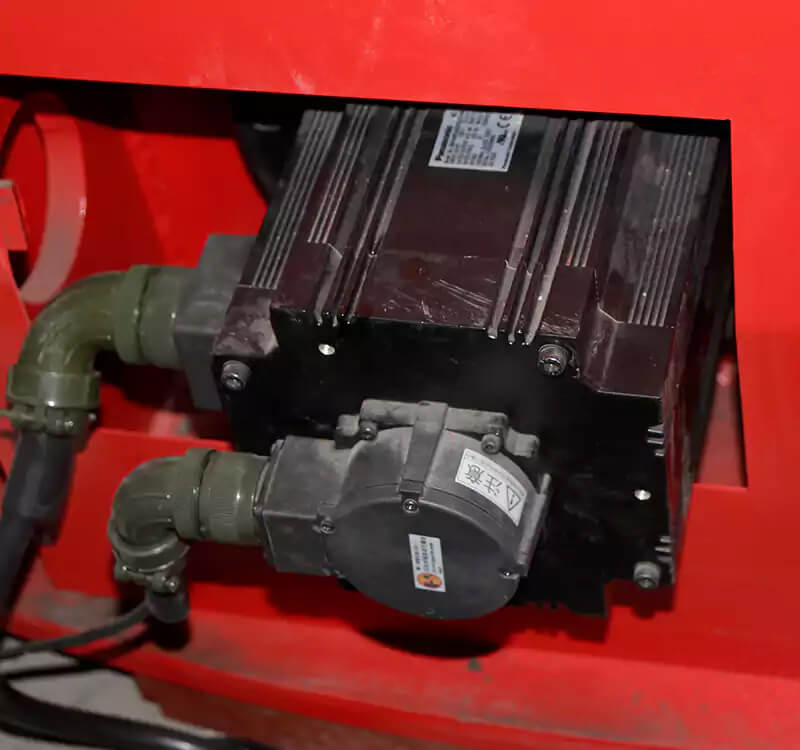

The welding turntable is mainly composed of a slewing table, a large high-intensity slewing support, a large torque reducer, a variable frequency brake motor, a conductive device, and an electrical control system. The rotary speed of the rotary table is variable frequency stepless speed regulation. The rotary table is composed of a rotary table and 8 legs.

The rotary welding turntable is provided with a conductive device between the box-shaped beam and the workbench, thereby forming a conductive circuit of welding the ground wire. Insulation treatment is adopted between the conductive device and the beam to prevent the bearing from over current and cause damage to equipment components. The conductive rod in the conductive device is a copper rod. The contact surface between the conductive column and the workbench is smooth and flat, but not painted, to ensure good conductivity and prevent the copper rod from sticking to the workbench after overheating.

Features:

1. The single-axis horizontal servo positioner is mainly composed of an integral fixed base, a rotary headstock, a horizontal rotary disc, an AC servo motor, and an RV precision reducer, a conductive mechanism, a protective cover, and an electrical control system.

2. The fixed base is welded with high-quality profiles. After annealing and stress relief, it undergoes professional mechanical processing to ensure high-precision processing and use accuracy at key locations. The surface is sprayed with rust-proof exterior paint, which is beautiful and generous. The color can be customized according to customer requirements. custom made;

3. The rotary headstock is made of high-quality steel, which can be used for long-term durability and stability after welding and annealing and professional machining.

4. The horizontal turntable is welded with high-quality profiles and professionally processed after annealing treatment, which can ensure the smoothness of the use surface and its stability. The upper surface is machined with thread holes with standard spacing, which is convenient for customers to install and fix. Positioning tooling

5. The AC servo motor and RV reducer are used as the power mechanism to ensure the stability of the rotation, the accuracy of the positioning, the long durability and low failure rate;

6. The conductive mechanism adopts brass as the conductive mechanism, which can play a good conductive effect, and the conductive base adopts overall insulation, which can effectively protect the servo motor, robot, and welding power source;

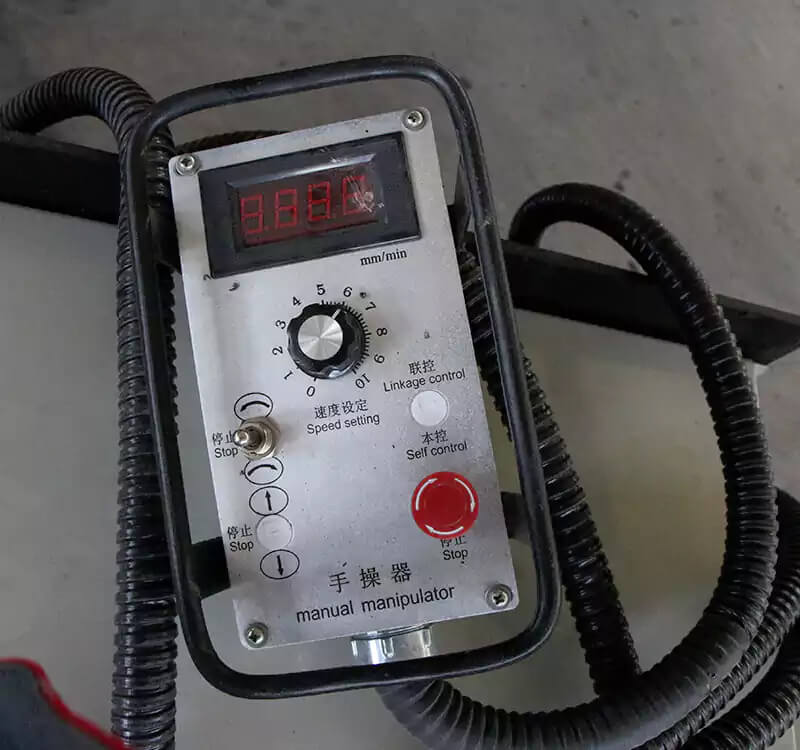

7. The electrical control system uses Japanese Omron PLC to control the positioner, with stable performance and low failure rate. Electrical components are selected from well-known brands at home and abroad to ensure the quality and stability of use.

Technical parameters:

| Model | HZT100 | HZT200 | HZT300 | HZT400 | HZT500 |

| Max lading weight(T) | 10 | 20 | 30 | 40 | 50 |

| Table size(mm) | 1800 | 2000 | 2500 | 4000(With extended legs) | 5000(With extended legs) |

| Rotatring angle(°) | N*360 | ||||

| Rotatring speed(rpm) | 0.06-0.6 | 0.05-0.5 | 0.04-0.4 | 0.016-0.32 | 0.016-0.32 |

| Adjustment speed mode | Frequency step-less adjustment (continuously adjustable) | ||||

| Rotatring powee(KW) | 1.5 | 2.2 | 3 | 4 | 5.5 |

| Max eccentricity(mm) | 200 | ||||