position: HOME > PRODUCTS > Welding Positioner

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

The price of the machine will be different due to factors such as parameters and configuration. For specific prices, please contact our sales staff. He will help you choose the appropriate parameters and configurations and will give you a quotation.

Product introduction:

The mechanical part of the Large-tonnage rotary welding positioner turning table is mainly composed of a rotation mechanism, a turning mechanism (an elevating mechanism), and a frame. The workpiece rotation and the workpiece turning (lifting) are servo-driven. Each servo motor is equipped with a precision RV reducer, For precise positioning.

Features:

1. Servo motor and precision reducer shaft hole adopts a direct connection structure, which has high transmission accuracy.

2. Rotary pinion, turning pinion, and supporting external teeth adopt a special backlash-free meshing structure.

3. Use heavy-duty precision slewing bearings with high bearing capacity, small backlash, and a large design margin, so as to reduce the amount of axis runout after the workpiece is turned over and ensure position accuracy.

4. The work plate is turned over by an AC motor. The two-stage worm gear and worm reduce the speed. It has a self-locking function and is more reliable.

5. It adopts a manual control box operation, which is convenient and flexible. The linkage interface is reserved in the control cabinet to achieve linkage control with other equipment, such as welding manipulators, gantry welding machines, and other welding equipment.

Technical parameters:

| Model.No | ZHB-300 | ZHB-400 | ZHB-500 |

| Load capacity(T) | 30 | 40 | 50 |

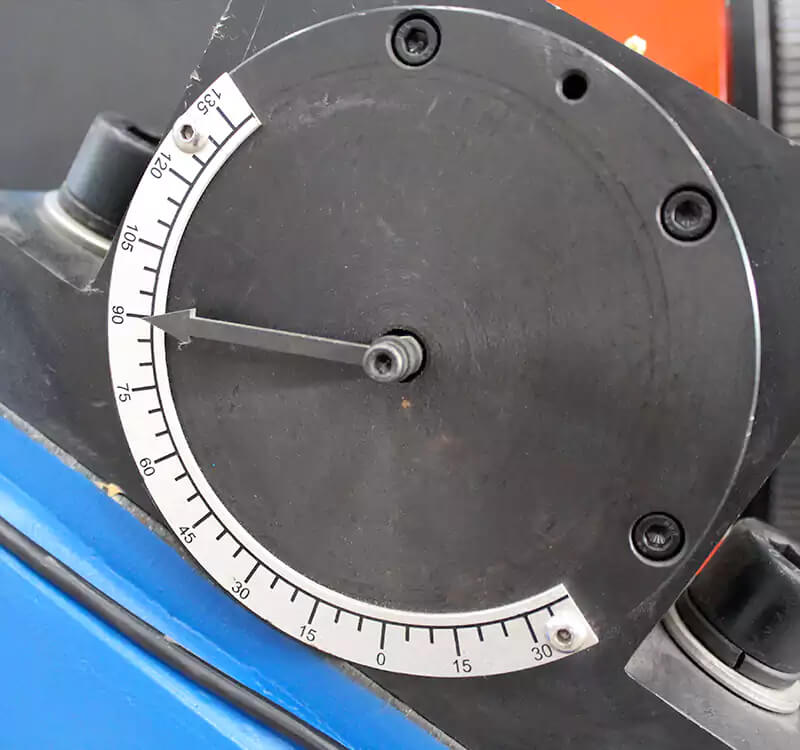

| turning angle(°) | 120 | 90 | 90 |

| Table turning speed(rpm) | 0.15 | 0.1 | 0.1 |

| Rotating speed(rpm) | 0.028-0.56 | 0.028-0.56 | 0.028-0.56 |

| Max centroidal distance(mm) | 630 | 700 | 800 |

| Max eccentricit(mm) | 200 | ||

| Max diamerer(mm) | 4300 | 5200 | 5800 |

| Table size(mm) | 3000 | 4000 | 4000 |

| Adjustment speed mode | Frequency stepless governor | ||

| Rotating power(KW) | 7.5 | 11 | 15 |

| turning power(KW) | 11 | 15 | 18.5 |