position: HOME > PRODUCTS > Welding Positioner

2015 Hua Fei CNC company dinner

How to choose a suitable welding positioner?

How to maintain the welding positioner?

Rescue measures for CNC cutting machine with large cutting error

How to protect a welding positioner?

How to purchase a good welding positioner?

Maintenance method of special welding chuck for positioner

How much do you know about the classification of the welding rotators?

Structure Types of Welding positioners

The 8 principles for choosing a welding positioner

Common fault problems and solutions of welding positioner

The price of the machine will be different due to factors such as parameters and configuration. For specific prices, please contact our sales staff. He will help you choose the appropriate parameters and configurations and will give you a quotation.

Product introduction:

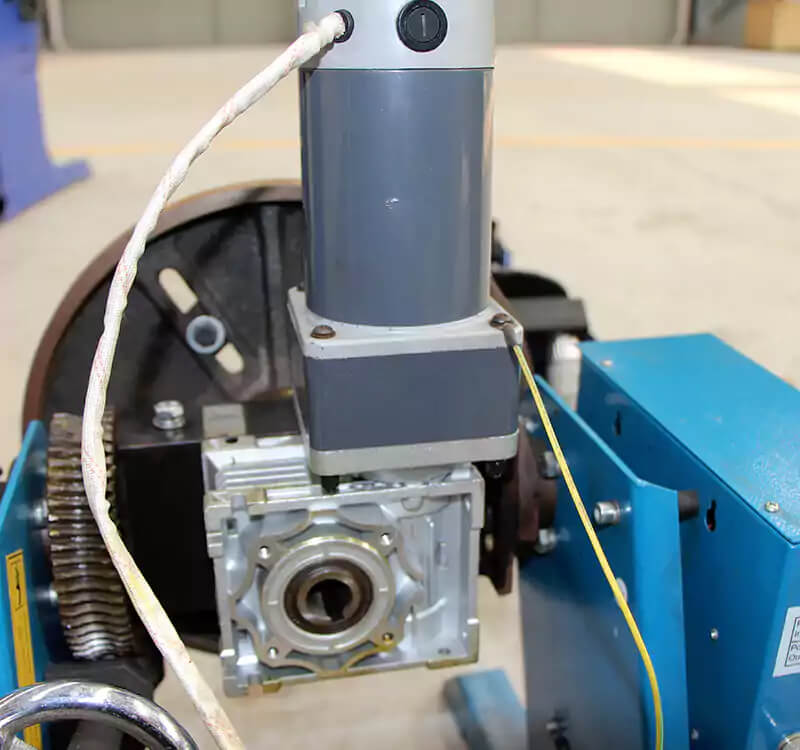

The small pipe welding positioners adopts DC motor to realize the step-less speed regulating, and microprocessor control to reach the linkage of positioner with a welding machine. This positioner is designed with professional anti-electromagnet to avoid high-frequency interference. The dynamical system we equipped is a worm gear reversal unit with a self-locking function. The working table rotation angle is 0~90°, can realize step-less rotation. Equipping with welding head frame, adjusting unit, guide rail, and the pneumatic tip can realize automatic welding.

Configuration:

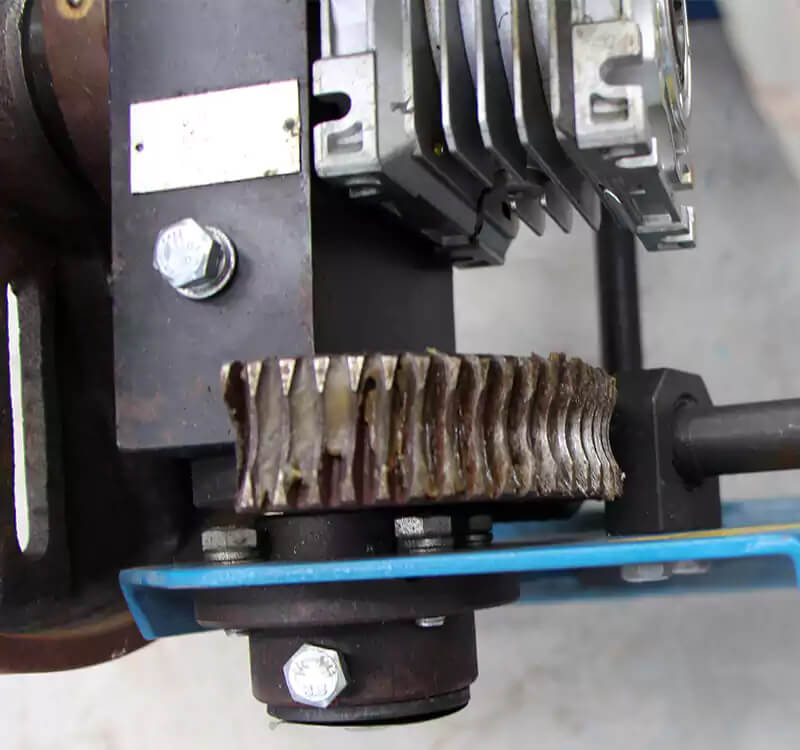

1.Slewing drive

(1) The slewing drive should achieve stepless speed regulation and can be reversed.

(2) Within the range of slewing speed, the speed fluctuation in the maximum load shall not exceed 5%.

2.Tilt drive

(1) The tilt drive should be stable, without shaking under the maximum load, and the whole machine must not overturn. If the maximum load Q exceeds 25kg, it shall have a power drive function.

(2) There shall be a limit device to control the inclination angle, and there shall be an angle indicator.

(3) The tilting mechanism must have a self-locking function, which does not slide under the maximum load, which is safe and reliable.

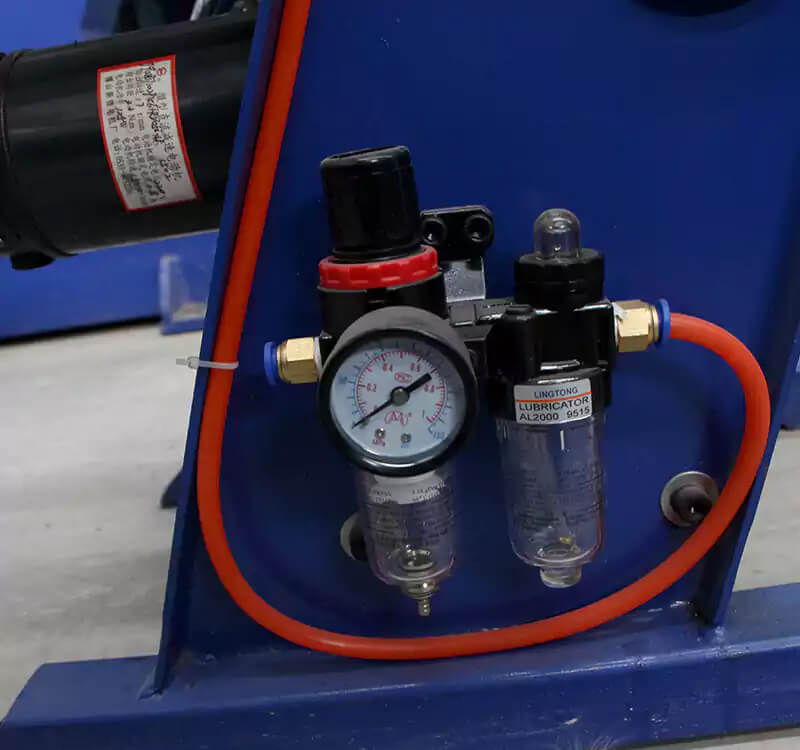

3.Other

(1) The control part of the positioner shall be provided with a linkage interface for automatic welding.

Features:

1. Quality assurance, one year warranty, truly customer-centric;

2. Fast delivery time, convenient transportation, adjacent to Jinan logistics center, timely delivery;

3. Small footprint, easy to use;

4. Integrated production and sales office, factory, and customer seamless docking, tailor-made products.

Technical parameters:

| Model | BW1-01 | BW1-05 | BW1-1 | BW1-3 | BW1-6 | |

| Basic loading(kg) | 10/5 | 50/25 | 100/50 | 300/150 | 600/300 | |

| Rotating speed(r/min) | 2-10 | 1-7/2-15 | 1-7/2-15 | 0.2-2 | 0.2-2 | |

Turning speed(r/min) | Manual turning | Manual turning | Manual turning | Manual turning | 0.37 | |

| Turning angle(°) | 0~90 | |||||

| Work table diameter(mm) | 180 | 320 | 340 | 450 | 700 | |

| Ground clearance height of turning center(mm) | 170 | 310 | 310 | 450 | 570 | |

| Allow workpiece off-center(mm) | Eccentricity | / | / | / | 50 | 100 |

Centroidal distance | / | / | / | 100 | 150 | |

| Rotating motor power(kw) | 0.01 | 0.12 | 0.12 | 0.2 | 0.4 | |

| Turning motor power(kw) | / | / | / | / | 0.55 | |

| Shape size | L(mm) | 330 | 500 | 500 | 500 | 780 |

| W(mm) | 270 | 320 | 340 | 520 | 700 | |

| H(mm) | 215 | 420 | 420 | 550 | 710 | |